Bottom of the Barrel Upgrading

UFR

Increase Economic Capacity with Guard Bed

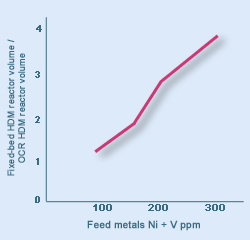

CLG’s Upflow Reactor (UFR®) process enables refiners to increase capacity and improve product quality from a fixed bed RDS reactor. Like OCR®, UFR is an upflow guard-bed reactor that is added to the processing scheme before the fixed bed RDS unit. However, it is less expensive to implement than OCR because it does not include the on-stream catalyst replacement transfer system.When adding a UFR reactor, refiners can increase feed throughput and/or process heavier feeds with higher levels of contaminant metals while maintaining excellent product qualities. UFR provides lower pressure drop increase across the reactor loop, which would be realized if a traditional downflow fixed bed reactor were added. Consequently, capacity of the system can be increased by as much as 50 percent.

they are operated in conjunction with UFR unit.

UFR Key Advantages:

- Low pressure drop, no need to change out recycle compressors

- Low plugging tendency due to the slightly expanded catalyst bed

- Opportunity to increase capacity as much as 50% in limited plot space

- Ability to process less expensive heavy, high metals feedstocks

- Prevention of guard-bed plugging problems

- Ability to increase feed rate due to the low pressure drop across the reactor

- Ability to add catalyst transfer system later

- Longer life of downstream fixed bed catalyst